The photovoltaic manufacturing field is advancing rapidly, with technological innovations in processes and engineering arriving at a relentless pace.

Recently, a technical term has been frequently mentioned within the industry and seems to be leading a new wave of photovoltaic technological innovation.

That term is 0BB.

0BB stands for “zero busbar” technology. BB represents “busbar,” the main grids on photovoltaic cells. The preceding number indicates the number of busbars.

Trends often move in the opposite direction. Over the past decade, photovoltaic technology experts have painstakingly increased the number of busbars from 2 to 20. However, there is now a major reversal, returning to “zero.”

Since last year, leading photovoltaic companies such as Trina Solar, Tongwei Co., Jinko Solar, Chint New Energy, Risen Energy, and others have been heavily researching 0BB technology, placing high hopes on it. Canadian Solar mentioned in its 2023 annual report, “With the continuous development of photovoltaic technology and changing market demands, 0BB technology is expected to become a mainstream technology in the photovoltaic industry in the future.”

So, what exactly is 0BB technology? Why has it risen to prominence? What impact will it have on the industry?

The Turning Point of Busbar Technology

When sunlight hits a photovoltaic cell, it generates current through the photovoltaic effect. However, this current cannot be directly used and must be collected and extracted. This is where busbars come in.

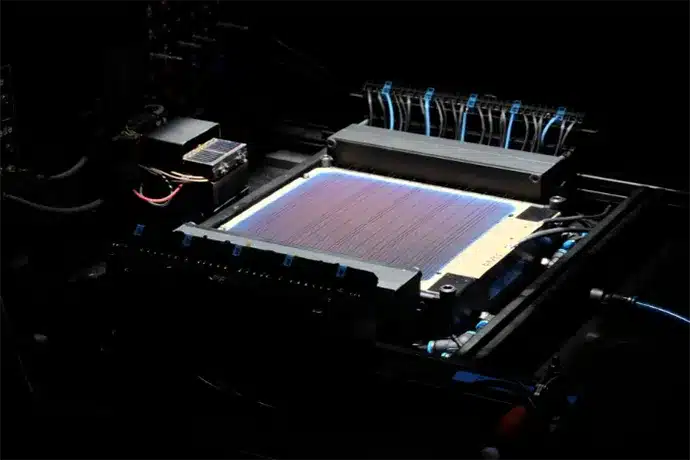

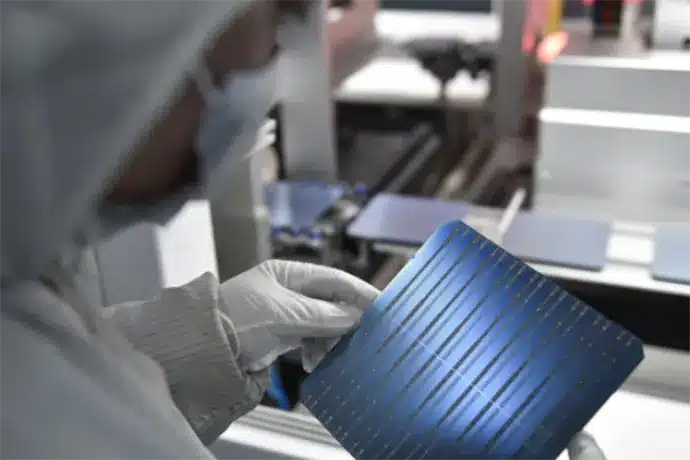

Currently, most photovoltaic cells use silver busbars attached to the cell surface. They are divided into main busbars and finer grids, with the finer grids being thinner. After the current is generated, it flows through the finer grids to the main busbars, which then transfer the current to copper ribbons for extraction.

Since the first practical monocrystalline silicon solar cell was made by Bell Labs in the USA in 1954, 70 years have passed.

The busbars on photovoltaic cells have continuously evolved in material, number, and width. The number of main busbars increased from 2BB to as many as 20BB by 2023.

Increasing the number of busbars brought several benefits, such as reducing the overall amount of silver paste needed and minimizing power loss due to the shorter current flow distance in the finer grids.

However, recent trends indicate a turning point for busbar technology. A completely opposite approach suggests simplifying the current transmission path by eliminating main busbars, allowing finer grids to connect directly with solder points and ribbons. This is the essence of 0BB technology.

0BB technology can be applied to various technical routes such as TOPCon, heterojunction (HJT), and back-contact (BC) technologies, making it a significant focus in the photovoltaic industry’s technological advancement.

Why 0BB?

Why are photovoltaic companies now keen on 0BB technology instead of increasing busbars? Compared to existing SMBB, 0BB offers several advantages:

Power Enhancement

Removing busbars reduces shading on the cell surface, increasing power generation. Additionally, with more densely distributed solder points, the current’s transmission path in the finer grids is shorter, reducing power loss.

Cost Reduction

Traditional busbars are made of silver paste, which is a significant cost component in photovoltaic cells. Removing busbars reduces the use of silver, thus lowering the overall cost.

Higher Quality

0BB technology’s smaller and more numerous solder points distribute stress more evenly across the cell, reducing the likelihood of cell cracking or grid breaks. This improves manufacturing yield and allows for the use of thinner silicon wafers.

Sparking a New Wave of Technological Competition

0BB has obvious advantages, has become the next round of technology competition hotspot.

Some professionals expressed that in 2024, ‘0BB technology’, which eliminates the main grid and significantly reduces the consumption of silver paste, is setting off a new round of technological innovation to “reduce costs and increase efficiency”.

Whether it is TOPCon, HJT, or BC, most companies have already started the layout of 0BB technology.

TOPCon leading enterprise Jinko Solar said on April 23 in the results of the meeting, “this year the company has completed all the introduction of laser-assisted sintering technology, 0BB technology to complete the pre-testing, can be more significant to improve the power and reduce the cost, according to the company’s planning to gradually import.”

HJT companies are more enthusiastic about the development of 0BB technology. Due to the HJT technology route in the silver paste consumption is more, so 0BB technology for HJT cost reduction is more obvious, is considered to be the HJT enterprises in the technology route of the fight to break out of the key.

Although in the 0BB technology development and application, enterprises you catch up, but 0BB technology is still facing a lot of problems need to be solved, including how to guarantee the consistency of welding, how to detect the efficiency and so on.

One of the more pressing is the reliability challenges posed by 0BB technology.

0BB technology challenges encountered

Currently, the mainstream fine grid and solder joints are a combination of silver and glass, the structure of the loose enough to stabilize, while the solder tape is made of copper. Silver and copper have different chemical and physical properties, the two welded together is difficult to solid, once there is an external tension or thermal expansion and contraction and other circumstances, the two are easily detached from the photovoltaic cell will not work.

This problem, there have been enterprises based on manufacturing process innovation launched a response to the policy.

However, there is no end to technological innovation. 0BB technology in the photovoltaic industry at the same time, the future of what difficulties to overcome, is not yet known. This sub-track has not received much attention in the past. In recent years, as the photovoltaic industry competition heats up, only to highlight its importance.

Participate in this technology “race” in the enterprise, if you can extend the direction of the 0BB continued technological innovation, or will be able to get to the photovoltaic industry’s future pass.