In solar systems, the spotlight often falls on solar panels, the mechanism converting sunlight into usable current. Yet, these power systems rely not just on solar panels but also on specialized solar cables, pivotal in propelling the green energy revolution! For newcomers in the photovoltaic industry, understanding this aspect is crucial.

What Are Solar Cables and Solar Wires?

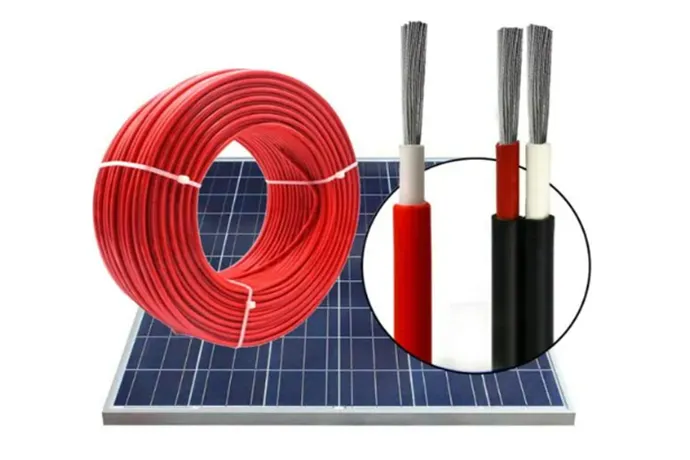

Solar cables and wires within photovoltaic systems serve as electrical wiring for power generation. These cables connect solar panels to other electrical devices in the design, facilitating the transmission of power from one point to another when needed. They contain circuit components and act as conduits for power transfer.

Specifically, solar cables transport the direct current generated by solar panels to the inverter or battery of a power station. Subsequently, the DC power gets converted to AC power, catering to charging appliances like refrigerators, air conditioners, and ovens.

Thoughtfully planned and correctly installed solar cable networks ensure the safety and optimal functioning of photovoltaic systems.

Solar Wires vs. Solar Cables

Solar Wires

Types of Solar Wires for Photovoltaic Systems

Various types of solar wires are used to connect components within photovoltaic systems, including solar panels, inverters, charge controllers, and batteries. Selecting the right type of solar wire for a photovoltaic system is crucial for its operation and efficiency. For instance, using the wrong solar wire might fail to provide the correct voltage and power to electrical devices, resulting in incomplete battery charging.

Categorizing Solar Panel Wires by Composition

Generally, solar wires come in two types: solid-core wires or stranded wires. Specifically, solid-core wires contain a single metal core, whereas stranded wires consist of multiple twisted conductors.

Sheathing insulates single-core wires, although bare wires exist too. Solid-core wires are recommended for static applications, especially residential wiring. They have a tighter diameter compared to stranded wires but carry the same load. The cost per wire is lower but suitable only for smaller specifications.

Stranded solar wires comprise multiple twisted conductors covered with sheathing to form a ground wire. Twisted solar wires are more flexible and can endure frequent movements. For installations in areas prone to strong winds or periodic vibrations, standard wires are recommended. Due to multiple conductors in one run, stranded wires exhibit better conductivity. However, stranded wires have a larger diameter and cost more. They are ideal for large outdoor installations.

Categorizing Solar Panel Wires by Material

Based on material type, solar panel wires are divided into copper wires and aluminum wires.

Copper wires bear more current than aluminum wires as they possess better conductivity, flexibility, and heat resistance. In other words, a thin copper wire can carry more current than an aluminum wire of the same size.

Though aluminum solar wires are more economical, they are brittle and have poor resistance to high/low temperatures. Opting for wires embedding high-quality copper cores ensures the safety of solar energy systems and extends their lifespan.

Guide to Solar Wire Colors

Coded colors of solar wires make executing and planning wire schemes easier. The colors of solar wires indicate their purpose and function within the solar system. This is crucial for future troubleshooting and maintenance. National electrical codes dictate conductor insulation and application. The color coding for alternating current (AC) and direct current (DC) varies. Here’s a quick color coding guide to facilitate your wire installations:

For AC Power Applications:

Red, black, or other colors are suitable for non-grounded hot applications.

White indicates grounded conductors.

Green or bare is used for equipment grounding.

For DC Power Applications:

Red denotes positive:

White represents negative or grounded conductors.

Green or bare is used for equipment grounding.

While installing electrical systems, it’s essential to adhere to the National Electrical Code (NEC) recommendations. Additionally, if uncertain about the conductors and insulations to use in specific applications, seeking help from certified electricians is advisable.

Solar Cables

Types of Solar Cables

Different types of cables are required in solar power generation projects, encompassing both direct current (DC) and alternating current (AC) cables.

Direct Current (DC) Solar Cables

DC solar cables are single-core copper cables insulated and sheathed. They are employed for photovoltaic solar panels and can be module cables or string cables.

Moreover, they come equipped with appropriate connectors and are pre-installed within the panels. Hence, they cannot be altered. In some cases, a string DC solar cable is needed to connect it with other panels.

Solar DC Main Cables

Main DC cables are larger collector cables. They connect positive and negative cables from the generator junction box to the central inverter.

Additionally, they can be single-core or twin-core cables. Single-core wires with dual insulation offer practicality and high reliability. For connections between solar inverters and generator junction boxes, it’s preferable to use twin-core DC cables.

Experts generally favor outdoor installations of main DC solar cables. Their sizes typically range from 2mm, 4mm, to 6mm.

Tip: To prevent short circuits and grounding issues, keep cables with opposite polarities separate from each other.

Alternating Current (AC) Connection Wires

AC cables link the solar inverter to protective equipment and the grid interconnection. For small-scale photovoltaic systems equipped with three-phase inverters, a five-core AC cable is used.

The wire distribution is as follows:

Tip: If your photovoltaic system has a single-phase inverter, a three-core AC cable is employed.