Find Out The Latest Show News From 2024 !

Leading Global Consumer PV Certification IEC TS 63163: More Reliable, Safer, Higher Standards

INTERNATIONAL AUTHORITATIVE CERTIFICATION

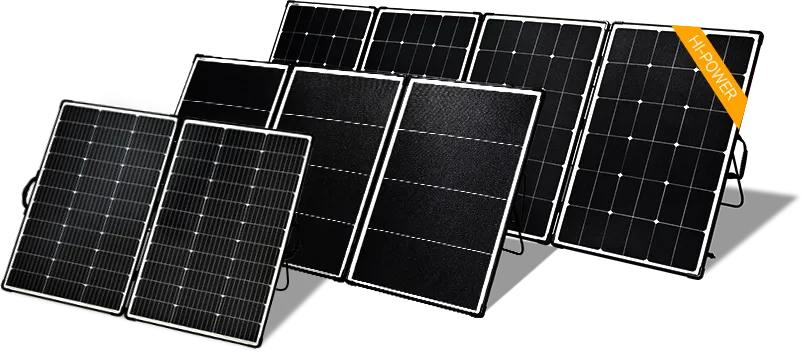

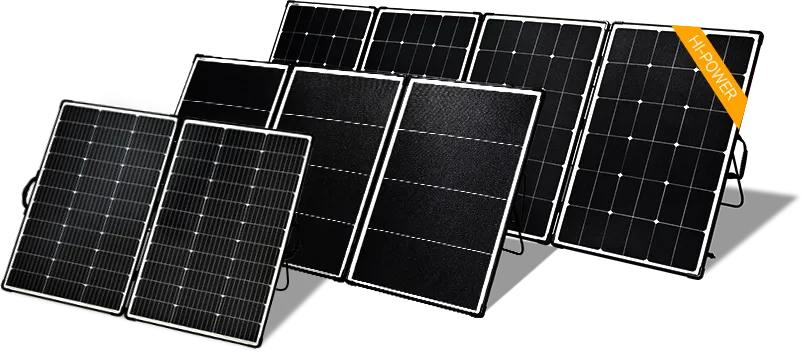

Balcony Solar Panels Rigid Solar Panel

Flexible solar panels

TF series

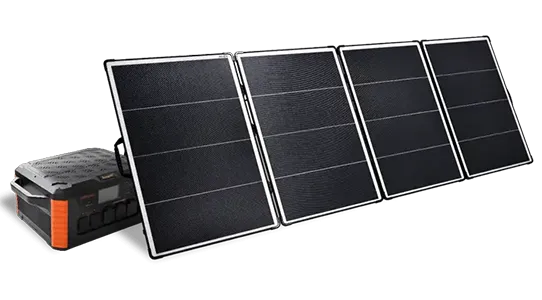

Camping solar panels

Hi-Power D

PV Certification IEC TS 63163

ABOUT US

Brand Belief

One world, one home, blue skies

Production Experience

16 years of professional manufacturing

R&D Technology

Patented material design, the world’s first original

Manufacturing Strength

Advanced production equipment, annual output 160MW

Technical Advantages

R&D Of Patented Material

Innovative Technology, High-efficiency Solar Panels

Photovoltaic Application Solutions

Modular Use,

Multi-scenario Application

APPLICATION SOLUTIONS

We are producing custom off grid solar panels for more application scenarios.

Frequently

Asked Questions

Q1: Get to know Sungold?

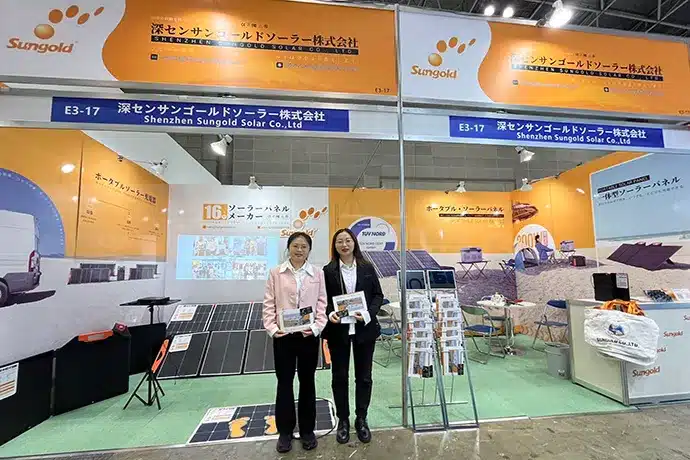

A: Sungold is a state-recognized PV high-tech enterprise with 16 years of experience in the application and manufacturing of off grid solar panels. Sungold is the partner of many brand-name customers around the world. Sungold is the partner of many global brands. We carry the dream of creating a blue sky with more than 300 employees and customize exclusive solar solutions for our customers.

Q2: What products does Sungold currently offer? Are there solutions for different industries or specific needs?

A: Sungold offers flexible solar panels, portable solar panels, and rigid solar panels. We can provide customized solutions for various applications based on our customers’ industries and specific needs. We have extensive experience in solar application scenarios such as balconies, RVs, marine,camping, gardens and anything off-grid solar system.

Q3: How about after-sales, what professional support will be available?

A: Undertaking more than ten years of after-sales as well as technical engineers can solve your concerns in all aspects. We provide you with all the pre-filled documents, all the necessary data sheets can also be downloaded from our website. All necessary product installation steps and short product instructions and videos will also be provided to you. We will also meticulously communicate with you about the conditions that must be met for your project before purchase so that you get the product you are happy with.

Q4: I have some projects with specific design needs that require PV modules, how can I fulfill them?

A:1、First of all, when you have specific needs, you may want to give some necessary information about the conditions, such as the application scenario of the product, the environment, what is the size and voltage of the demand, what is the equipment to be carried, and what are the needs to be met. So that our professional sales engineers will judge which products are more suitable for you according to your information, and design a set of photovoltaic project programs for you. Remember we have 15 years of experience in ODM one-stop solution, trust us!

2、If you need solar panels for a photovoltaic roof. We have monocrystalline 450W solar panels designed for off-grid systems with a PV controller and Sungold inverter to power homes. Also, we can use batteries or home portable energy storage to store power for evening peaks.

Q5: What is the quality and warranty of flexible panels, foldable solar panel, and glass modules?

A: 1. Our flexible solar panel TF series utilizes a highly elastic and ultra-lightweight composite molecular material developed by us, which guarantees the product’s impact resistance and a five-year warranty.

2. foldable solar panels use a unique product process, product corrosion resistance, and waterproof performance, including the Hi-Power series of portable solar panels with a five-year warranty.

3. Customized size for non-standard glass modules. Unique appearance and design solutions to meet your different application needs. Rigid solar panels have a ten-year warranty and twenty-five-year service life.

Q6: Can we customize the solar panel dimensions and voltage?

A: Of course! The customized dimensions and voltage of solar panels are based on demand. During the fabrication process, solar PV modules of appropriate size and voltage can be selected according to the design requirements and actual situation. The process of customizing the size and voltage may involve material selection, the way the panels are connected, and the adjustment of design parameters. Overall, customizing the size and voltage of PV modules is a flexible process that needs to be adjusted and fabricated according to specific needs and requirements.

Q7: What certifications and tests have the products passed

A: Usually our products have passed harsh tests, such as salt spray resistance test, double 85 test, anti-treading test, impact resistance test, waterproof test, etc. We comply with CE-EMC, CE-LVD/ROHS/IEC663163/FCC/UL/TUV certification for export products. In particular, our 400w solar panel has obtained the photovoltaic consumer certification IEC63163

Q8: How Much Do Solar Panels Cost?

A: We provide ODM customized service for our customers. Each customer’s specific situation is different. Custom solar panels prices can be matched by contacting our professional customer service staff. You will receive detailed product information, exclusive customization suggestions, and preferential product prices. Send us an email and let’s have a pleasant exchange!

Q9: What is the company's lead time? Can we meet urgent or expedited orders?

A: Our delivery time for solar panels for sale depends on the size and complexity of the order, and we are usually able to fulfill the delivery within a reasonable period. For urgent or expedited orders, we will do our best to meet the requirements of our customers and work closely with them to ensure timely delivery.

Q10: Does Sungold have initiatives on sustainability and environmental responsibility?

A: Sustainability and environmental responsibility are important concerns for Sungold. We are committed to reducing our environmental impact and have taken several steps towards a sustainable supply chain. We continually improve our manufacturing and operational processes, utilize environmentally friendly materials and technologies, and promote environmental awareness among our employees. Our goal is to provide our customers with quality products while protecting the environment and promoting sustainable development.

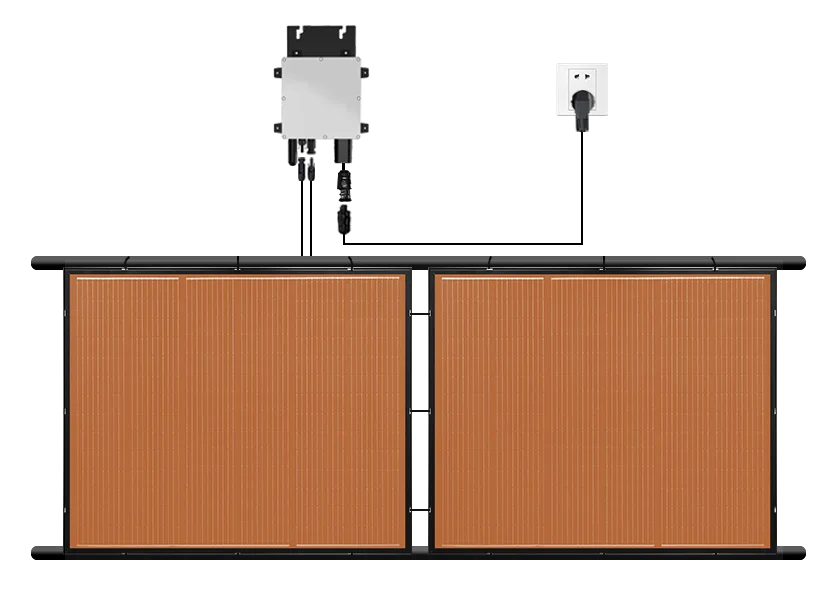

Customer Case 1

| Customer Needs : | Portable Solar Panels |

| Application Scenario : | Balcony, garden, outdoor camping |

| Personalization : | Balcony:Input voltage range of 22-50V for micro inverter Garden:1kwh-2kwh portable power station |

| Accessory Requirements : | With microinverter |

| Solar panel voltage : | Customized voltage 36.5v |

| Sungold’s customized solution : | Using portable solar panel Hi-Power series 300W with 350w micro inverter. The solar panels are made of shingle solar cells, which can be used in two strings and two parallels to keep the voltage at 36.5v to meet customer’s requirement. |

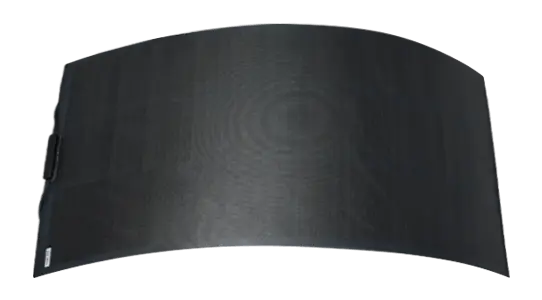

Customer Case 2

| Customer Needs : | All Black Flexible Solar Panels |

| Application Scenario : | Balcony |

| Personalization : | All black flexible solar panels; the size of a single solar panel is controlled at about 1*1M. |

| Accessory Requirements : | With microinverter |

| Solar panel voltage : | 685*930*2mm |

| Sungold’s customized solution : | Adopt TF-D series flexible solar panel. The solar panels are made of shingle solar cells and the size of a single solar panel is 685*930*2mm, not exceeding 1*1M.

Sungold provides 6 pieces of 120W all-black flexible solar panels with 600W micro-inverter to meet customer’s needs. The solar panels are made of shingle solar cells, which can be used in two strings and two parallels to keep the voltage at 36.5v to meet customer’s requirement. |

Get the latest news about sungold

Address: Hong Kong Convention Center

Exhibition Time: 4/13/2024 – 4/16/2024

Sungold Booth No.: 1AC23

Address: The Munich Trade Fair Centre Riem

Exhibition time: 06/04 – 06/05/2024

Sungold Booth No.: TBD

Address: Messe Munchen, Munich, Germany

Exhibition time: 6/19/2024 – 6/21/2024

Sungold Booth No.: A1.630G

We invite you to schedule an appointment and visit our booth in advance, where we’ll showcase our newest products and cutting-edge solar solutions.

Explore the latest in solar solutions

Gain expert insights and commentary

Dive into leading-edge industry information

Join Sungold at the 2024 Canton Fair: Exhibition Guide

Discover Sungold Solar Innovations at the Hong Kong Electronics Fair 2024

Sungold Innovative Solar Technologies Lead the Energy Revolution at World Smart Energy Week

INTERNATIONAL AUTHORITATIVE CERTIFICATION

Leading Global Consumer PV Certification IEC TS 63163: More Reliable, Safer, Higher Standards