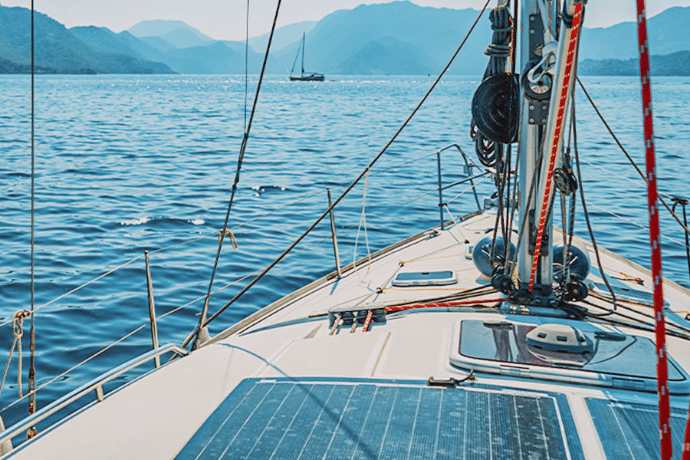

Flexible solar panels are a new type of solar PV module that is lightweight, flexible, and bendable for use on a variety of irregular surfaces, such as tents, cars, boats, etc. The advantage of flexible solar panels is that they can harness more solar energy, increase power generation efficiency, and save space.

However, flexible solar panels also have some challenges, one of which is the hot spot issue. Hot spots are localized overheating in some cells in the module due to uneven irradiation or partial shading, which can affect the performance and lifetime of the module and even cause safety hazards such as fire or explosion. Therefore, for flexible solar panels, it is very important to do a good hot-spot test.

What is the Hot-spot endurance test?

The hot-spot endurance test is a test method to evaluate whether solar PV modules can withstand the effects of hot-spot heating, such as the melting of solder joints or degradation of encapsulation materials, under uneven irradiation or partial shading. This test method is specified according to IEC 61215-2:2016 standard and consists of the following steps:

- Apply an illumination of 900-1100 W/m² to the front or back of the module, while applying a mask to a portion of the module’s cells so that its current is 0 or negative.

- Select a maximum temperature point within the masked area, measure its temperature and voltage, and calculate its power loss.

- Repeat the above steps until the highest temperature point and the maximum power loss point are found.

- At the highest temperature point and maximum power loss point, continue applying illumination and shading until the module fails or reaches 96 hours.

- The module is checked for visible damage or degradation of performance.

What are the criteria or indicators for the Hot-spot endurance test?

The criteria or indicators for the Hot-spot endurance test are mainly the following:

- The module must not show visible damage during the test, such as melted solder joints, cracked, discolored, or blistered packaging material, etc.

- The module must not show any degradation in performance at the end of the test, such as a reduction in peak power, open circuit voltage, short circuit current, or fill factor.

- The maximum temperature point and maximum power loss point of the module during the test cannot exceed the limits specified in IEC 61215-2:2016 standard, for example, the maximum temperature point cannot exceed 200°C and the maximum power loss point cannot exceed 5%.

What are the benefits of the hot-spot endurance test for flexible solar panels?

Hot-spot endurance tests can check the safety and reliability of flexible solar panels and prevent the risk of fire or performance degradation due to hot spots.

Also, it can improve market competitiveness and consumer confidence in flexible solar panels and meet the regulatory requirements of different countries and regions.

What are the disadvantages or limitations of the hot-spot endurance test?

Hot-spot endurance test also has some drawbacks or limitations, for example:

- Hot-spot endurance test is a manual simulation test method, which may not fully reflect the actual environmental conditions and influencing factors, such as wind speed, humidity, dust, etc.

- Hot-spot endurance test is a time-consuming and energy-consuming test method, which requires prolonged exposure and shading of the module, as well as precision instrumentation and equipment, which can increase the cost and difficulty of the test.

- Hot-spot endurance testing is a destructive test method that can cause irreversible damage to the module, rendering it unusable or unsellable.

How can hot-spot problems be prevented or mitigated?

To prevent or mitigate hot-spot problems, there are a number of measures that can be taken:

- When designing and manufacturing flexible solar panels, choose appropriate materials and construction to improve the flexibility and durability of the modules and reduce problems such as cell breakage or poor contact due to bending or folding.

- When installing and using flexible solar panels, avoid placing any objects or shading on the modules, keep the modules clean and ventilated, and avoid the modules from being affected by excessive mechanical stress or temperature difference, etc.

- When monitoring and maintaining flexible solar panels, check the working status and output parameters of the modules regularly, find and deal with any abnormalities or faults in time, use professional instruments and tools, and follow safety codes.

Conclusion

Flexible solar panels are a promising solar PV technology, but they are also challenged by hot-spot issues. the hot-spot endurance test is an effective test method to evaluate the safety and reliability of flexible solar panels under uneven irradiation or partial shading.

However, the Hot-spot endurance test also has some drawbacks or limitations that need further improvement and refinement. In addition, there are some measures to prevent or mitigate the hot-spot problem to improve the performance and lifetime of flexible solar panels.