In the field of modern energy technology, the portable photovoltaic panel, as an innovative technological achievement, has brought more efficient, convenient, and reliable solutions for solar energy utilization. This article will deeply analyze the technical principles, product features, application advantages, and performance in practical applications of the portable photovoltaic panel, leading readers to comprehensively understand this technology that leads the future energy trend.

What are the innovation points of the portable photovoltaic panel?

Structural innovation

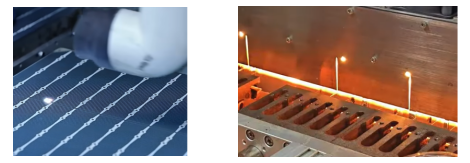

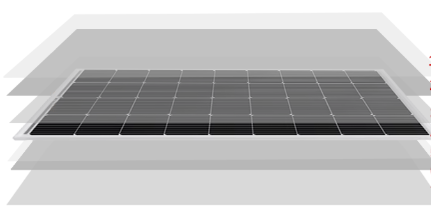

The Sungold bxf-plus portable photovoltaic panel adopts an integrated lamination process, including a front film, an adhesive film, patented composite materials, solar cells, and fabric. This structure ensures the overall stability of the panel, and each layer works together to achieve lightweight and flexibility.

Material innovation

Front film

A new material is selected as the front film with excellent performance. With a 93% high light transmittance, and the actual test shows that from -20°C to 60°C, the film can ensure excellent performance, with good weather resistance, ultraviolet resistance, damp and heat resistance, long-lasting adhesion, heat resistance, salt spray chemical and wind sand abrasion resistance, and reliable outdoor long-term verification.

Patented composite materials

The innovative design uses Sungold’s unique composite material to replace the traditional material for module packaging. The unique packaging reduces weight, enhances impact resistance, and protects the battery cells. The “Patented composite materials + solar cell + Patented composite materials” double-sided protective packaging disperses external forces, reduces the risk of hidden cracks, making the product lighter and tougher at the same time.

Eco-friendly cork fabric (optional)

The cork fabric has thermal insulation properties, with a low thermal conductivity coefficient, maintaining the stable temperature of the portable photovoltaic panel and improving the efficiency and lifespan of the battery cells.

packaging material

What effects does the innovation and breakthrough of the portable photovoltaic panel bring?

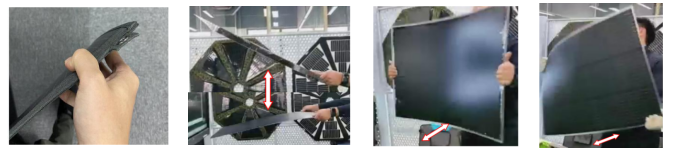

Excellent impact resistance

Trough a series of strict scene simulation tests, such as the 50W gentle integrated scene simulation of a single panel:

Local force test, about 15° – 30°.

Overall force bending test (long side bending).

Plane stepping test.

1 meter plane drop test.

0.8 meter corner drop

There is no battery cell fragmentation or hidden crack in the above scene simulations.

Even in the more extreme 1.5 – 2 meter horizontal throw test, although battery cell fragmentation and hidden cracks may occur, compared with traditional products, its impact resistance is still significantly improved. This strong impact resistance makes the panel more reliable when used in complex outdoor environments, reducing the risk of damage caused by accidental collisions or drops, and effectively extending the service life of the module.

Significantly reduced weight

Under the same power and voltage conditions, the portable photovoltaic panel has an obvious weight advantage compared with the conventional portable photovoltaic panel.

Under the same power and voltage, compared with the conventional portable photovoltaic panel:

① Weight of the gentle photovoltaic panel: 4.3kg;

② Weight of the conventional photovoltaic panel: 8.0kg.

The weight reduction ratio reaches 46%.

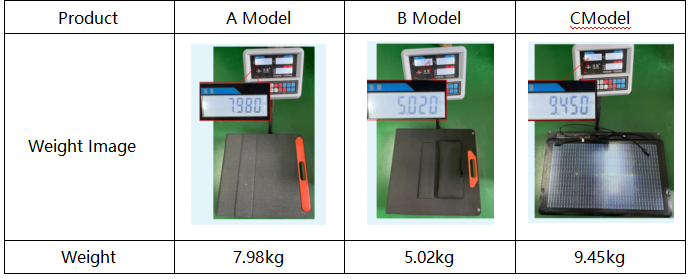

Weights of other competing products:

This lightweight design makes the panel easier to carry and install, especially suitable for outdoor mobile application scenarios such as hiking, camping, and field operations, greatly improving the convenience and flexibility of solar power generation.

Effectively reduced hot spot effect

The unique process reduces current passing through

The battery cells used in the portable photovoltaic panel adopt a new cutting process, which will reduce the current and reduce the risk of internal resistance heat spots. At the same time, the application of the new welding process optimizes the distribution and enhances stability and reliability.

The material and lamination method work together to protect

The use of Innovative Polymer Materials solar panels material can effectively protect the battery cells from external factors. The updated lamination method not only enhances the protection of the battery cells but also improves the impact resistance of the module.

Because these factors cooperate with each other, the portable photovoltaic panel performs well in controlling the hot spot effect, ensuring that the battery cells maintain good performance during long-term use, reducing power attenuation and portable photovoltaic panel damage caused by hot spot problems, extending the service life of the panel, and improving power generation efficiency.

Longer service life

- The new process controls the electrical performance of the battery cells and reduces the occurrence of hot spots;

- The optimized lamination process makes it more flexible, tougher, and bendable, and realizes lightweight to enhance the anti-drop performance;

- The protection level of IP67.

The above multiple factors can ensure the stability of the battery cells, maintain normal power output for a long time, and ensure that the module has a longer service life. Whether it is used outdoors for a long time or under various harsh climatic conditions, the gentle integrated module can show excellent durability and stability.

Better outdoor attributes

Portable folding design

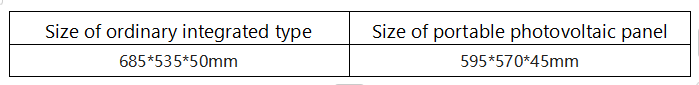

The folding design is portable. After folding, the size is small (under the same power, the volume of the portable photovoltaic panel is 16% smaller than that of the conventional portable photovoltaic panel), easy to store and carry, suitable for outdoor activities such as traveling and camping to charge equipment, realizing mobile portable power generation.

Adapt to various environments

With light weight and strong impact resistance, it is applicable to a variety of outdoor scenarios. It can work normally in complex terrains, providing stable power for users and meeting the power needs of outdoor activities.

Final thoughts

Product Specifications and Customization Services

Our company’s conventional gentle integrated products have two specifications, 4 * 50W and 8 * 20W, which can meet the power needs of various scenarios. If you are interested in other specifications, we can provide customization services. With a professional team, whether you have special requirements for power, size, or performance, we can customize it for you. If you need products or have questions, please feel free to contact us. We look forward to working together to create a clean energy future and providing you with more convenience and value.

Portable photovoltaic panel FAQ

- What is the customizable power range of the gentle integrated module?

The minimum single-board power verified and stabilized by our company is 7W, and the maximum power is 50W (verification is required for customizing power outside the conventional range). - What is the warranty and service life of the gentle integrated module?

The warranty is one year, and the service life is five years. - Does the gentle integrated module come with a bracket?

It does not come with a bracket and cannot be customized. If you need a bracket, you can choose the conventional integrated module. - What kind of connector does the gentle integrated module have?

The conventional connectors are MC4/DC/type C/USB, and they can be customized.