What are monocrystalline and polycrystalline solar panels?

You know what? At present, solar power is mainly the dominant market of monocrystalline, The last few years are polycrystalline, Why do these changes happen? Let me briefly analyze the following:

Solar cells are semiconductor devices that convert solar radiation directly into electrical energy based on the photovoltaic effect of semiconductors. The monocrystalline and polycrystalline manufacturing process is different and the composition is different, but the final product (rigid solar panel) is the same. The difference between the previous two is that the photoelectric conversion rate is different. Monocrystalline has always been more efficient than polycrystalline conversion, Even in the lab, this is the case.

At the price, the normal monocrystalline will be higher than the polycrystalline. The production cost of polycrystalline is far lower than that of monocrystalline, and the yield of polycrystalline is far greater than that of monocrystalline. But this is just relative to the previous years. Now, with the improvement of production technology, the demand for high efficiency conversion is expanding. Drive the whole monocrystalline production chain, the price of monocrystalline is equal to that of polycrystalline.

Monocrystalline solar panels

A monocrystalline solar panel is made from monocrystalline solar cells or “wafers.” Monocrystalline wafers are made from a single silicon crystal formed into a cylindrical silicon ingot. Although these panels are generally considered a premium solar product, the primary advantages of monocrystalline panels are higher efficiencies and sleeker aesthetics. Because a monocrystalline cell is composed of a single crystal, the electrons that generate a flow of electricity have more room to move. As a result, monocrystalline solar cells are more efficient than their polycrystalline solar cell counterparts. You will need fewer monocrystalline panels for your roof to produce more kWh of electricity than others, but they’re more expensive per panel.

Using single crystals provides higher efficiency than other solar panels, resulting in better power production for your home. However, the production process is expensive, so monocrystalline panels cost more. The process also creates an excess of wasted silicon material that can’t be reused for mono panels.

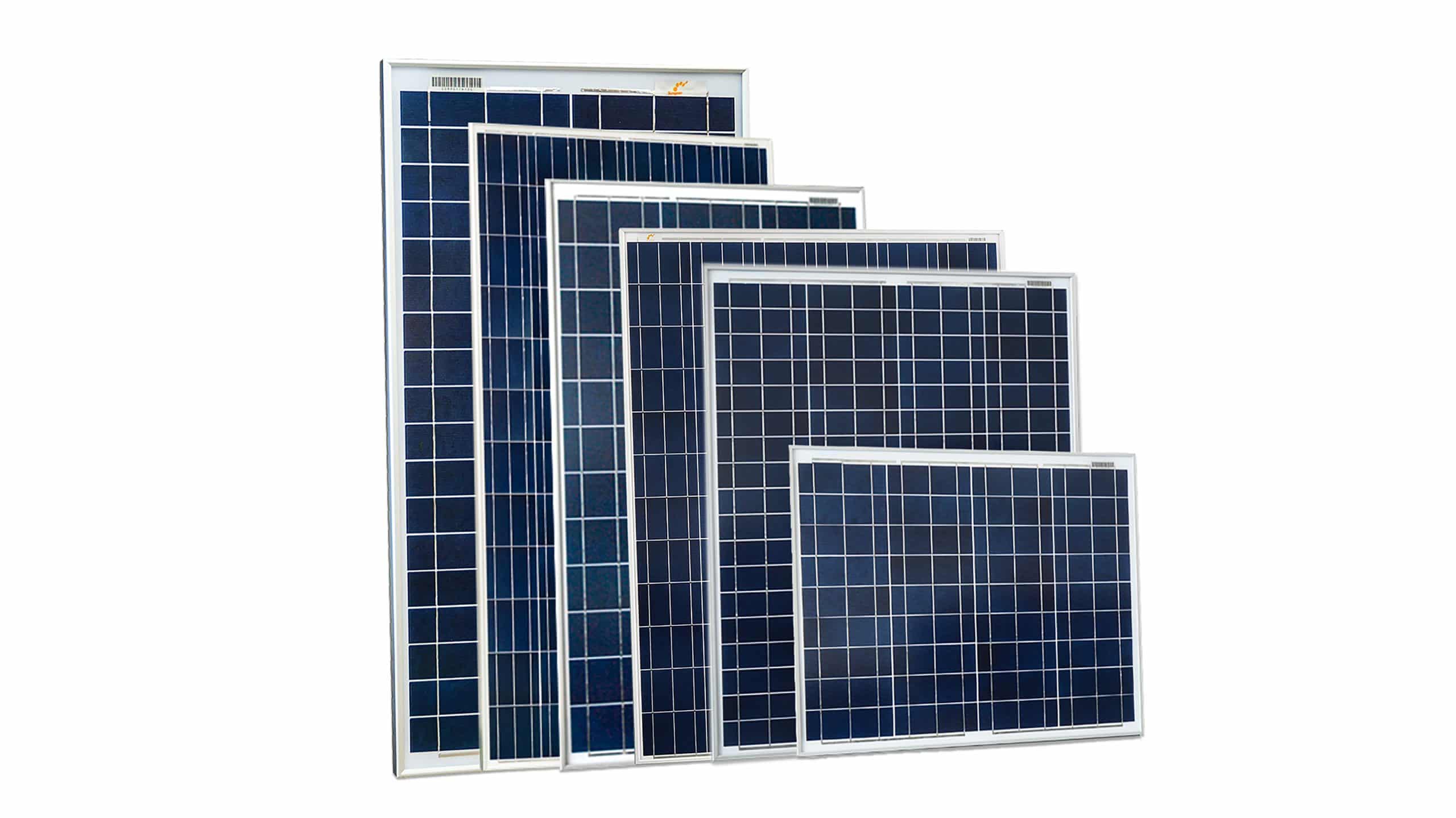

Polycrystalline Panels

Polycrystalline solar cells are composed of multiple fragmented silicon crystals. These fragments sometimes include the wasted silicon from the mono panel process. The silicon pieces are melted together to form polycrystalline solar cells. These multi-crystalline cells are formed and sliced into thin cubes.

Polycrystalline solar panels generally have lower efficiencies than monocrystalline cell options because there are many more crystals in each cell, meaning less freedom for the electrons to move. Due to the easier manufacturing process, these panels have a lower price point on average. In addition, polycrystalline solar panels tend to have a blue hue instead of the black hue of monocrystalline solar panels. Because they are less efficient than other panels, you will need more to provide electricity for your home, but their individual cost is lower

In addition, the material of monocrystalline is better than of the polycrystalline, not easily damaged in the production process. In addition to the appearance, the monocrystalline is usually monochromatic (usually blue and black). The polycrystalline color is very mixed, and it has a monochromatic blue color, it also has color.

What are monocrystalline and polycrystalline solar panels?

It’s all about the metrics. Here’s how monocrystalline and polycrystalline solar panels stack up against each other in a few key areas

| Factors | Monocrystalline Panels | Polycrystalline Panels |

|---|---|---|

| Average cost | More expensive | Less expensive |

| Efficiency | 18% to 23% | 13% to 16% |

| Panel appearance | Solar cells are a black hue | Solar cells have a blue-ish hue |

| Roof space | Lower temperature coefficient/more effective when temperature changes | Requires more roof space for installations |

| Typical life span | 25 + years | 25 + years |

| Temperature coefficient | Lower temperature coefficient/more effective when temperature changes | Higher temperature coefficient/less efficient in heat |

rv solar panels

mono solar panels for camping

Final thoughts

In summary, high-efficiency monocrystalline solar panels have solar cells made from a single silicon crystal while polycrystalline solar panels have solar cells made from multiple fragments of silicon crystals melted together. This manufacturing difference means that the spectral response of monocrystalline solar panels is higher, which gives them better performance. Although they are more expensive, the fact that they can produce more energy offsets their additional cost, especially knowing that their lifespan is at least 25 years. In addition, their black color is more discreet and works better with a conventional shingle roof. Monocrystalline solar panels are definitely the best type of solar panel.

So, monocrystalline is superior to polycrystalline in all aspects. Moreover, at present the monocrystalline development of conversion efficiency and flexibility is constantly developing. The highest efficiency is up to 26%. The flexibility is getting better and better, so in recent years semi-flexible solar panel is more and more widely used.